Products

Processed Glass

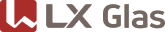

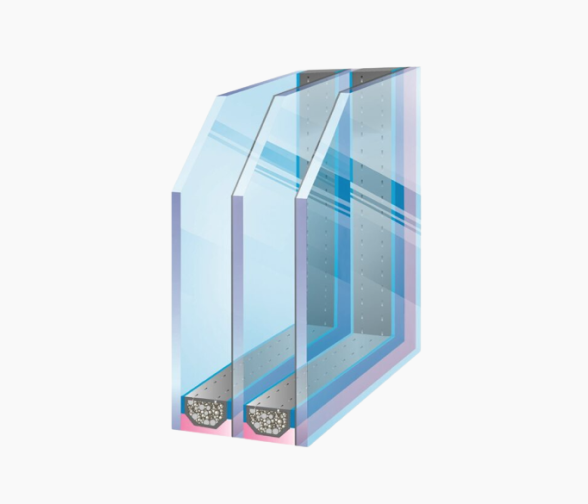

Insulated Glazing Unit

Insulated Glazing Units (IGUs) are energy-saving processed glass products that enhance insulation by creating an air gap between two or three panes of glass by using spacers. Different configurations can be constructed by using different types of glass, materials, and spacer sizes, as well as different gases in the inert gas layer.

Applications

• Residential: Flats, Detached houses, Multi-family dwellings

• Commercial: Offices, etc.

Color

• Clear, Green, Blue, Bronze, Gray

Specifications

• Thickness: 16~28mm

• Maximum dimensions: 2,650mm X 4,500mm

* This may change, depending on the composition of the glass.

Key features

Precautions for Installing Double Glazing

1. To fully ensure the performance of double glazing, window frames with excellent thermal insulation and airtightness must be used. When installing the frame, care must be taken to prevent impacts from opening/closing or warping from affecting the glass.

2. During window frame installation, if drainage channels are not provided within the frame, water accumulation may occur. This can cause swelling of the insulating glass sealant. Consequently, the adhesive strength of the sealed sealant within the insulating glass may deteriorate, leading to reduced durability and potential condensation forming inside the insulating glass unit.

3. Use silicone-based, polysulphide-based, or polyurethane-based sealants of the non-acidic type, which offer excellent watertightness and weather resistance.

4. The sealant used in double glazing is an organic material with a finite lifespan. To maintain its functionality over the long term, the installation method is crucial; therefore, standard installation procedures must be strictly adhered to.

5. When ordering insulating glass, note that no processing—such as cutting, edge finishing, or hole drilling—is possible after manufacture. Therefore, the size and shape must be specified accurately at the time of order.

6. Installed insulating glass may exhibit surface image distortion (distortion) due to internal contraction or expansion of the air layer. This occurs when the ambient temperature and pressure conditions differ from those during production, altering the temperature and pressure within the air layer.

Precautions for Processing Insulating Glass Units

1. When manufacturing insulating glass units using different types of glass, careful consideration must be given to the outer and inner panes to ensure no adverse effects on appearance, safety, or performance.

2. The aluminium spacers used must be cleaned spacers with all rolling oil completely removed.

3. The desiccant used must be a product with internal pore sizes of 3Å to enable selective adsorption of water vapour only.

4. Butyl is crucial as it not only fixes the spacer position during manufacturing but also blocks moisture ingress from the exterior. Therefore, the butyl line must be evenly adhered and show no breaks along all four edges after insulating glass unit fabrication.

5. Occasionally, fine rainbow-coloured striations may be observed on the inner or outer glass surfaces at specific angles. This is not a glass quality issue but a natural interference phenomenon arising from the high parallelism between the two panes of insulating glass.